Business

Are you getting ready to quote your next vacuum chamber project? Avoid common pitfalls with our complete vacuum chamber buying guide.

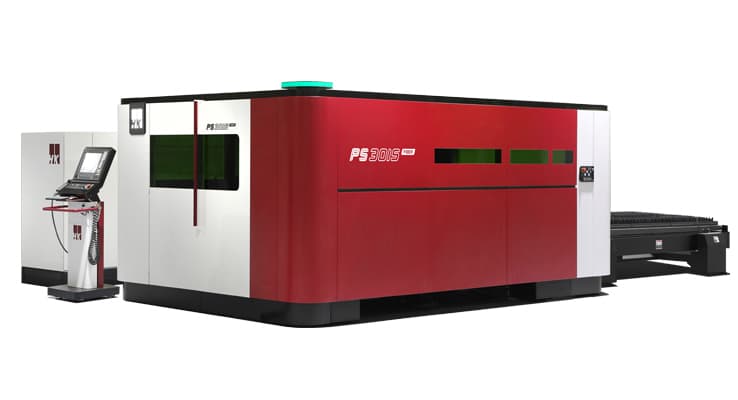

Gulf States Saw & Machine Co. specializes in custom sheet metal fabrication. Our Raleigh machine shop specializes in producing close tolerance parts for many industries.